Address

E02 No.509 Floor 5 Unit3 Building1 No.1700 Tianfu Avenue North Section High-tech district Chengdu City Pilot Free Trade Zone China(Sichuan)

Work Hours

Monday to Friday: 9AM - 6PM

Weekend: 10AM - 5PM

Address

E02 No.509 Floor 5 Unit3 Building1 No.1700 Tianfu Avenue North Section High-tech district Chengdu City Pilot Free Trade Zone China(Sichuan)

Work Hours

Monday to Friday: 9AM - 6PM

Weekend: 10AM - 5PM

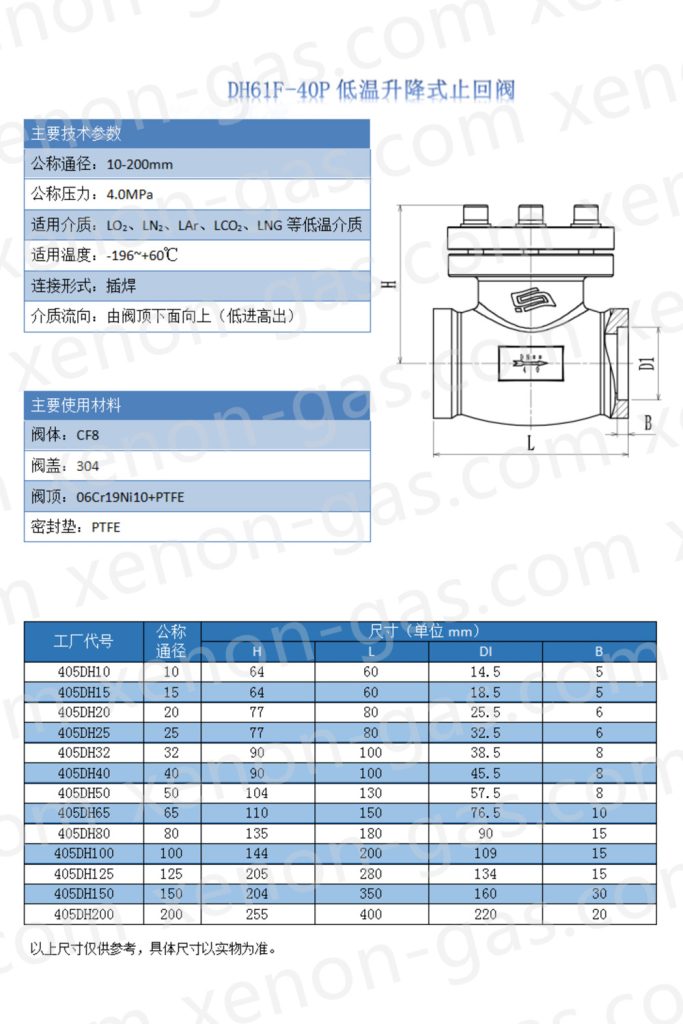

Valve overview:

Cryogenic check valves are mainly used in low-temperature storage tanks, tank cars and skid-mounted pipelines, and have the characteristics of preventing medium backflow and reliable sealing

Executive standard:

Design standard: GB/T24925-2019

Normal temperature sealing performance: GB/T26180-2011

Low-temperature sealing performance: G/T24925-2019

Installation and maintenance matters

When installing the valve, it should be noted that the flow direction of the valve mark should be consistent with the flow direction of the medium

Make sure the pipes are blown clean before installation

The valve core should be taken out during welding

After the pipeline installation is completed, open all valves and purge repeatedly to ensure that the pipeline is clean and free of residual impurities

It is recommended to use dry nitrogen or compressed air for pressure tests. It is strictly forbidden to use a low-temperature medium after a hydrostatic test.